Sustainable Operations

Throughout operations and the supply chain, there are many instances where more sustainable practices can be put in place. By rethinking how we approach using and re-using materials, Alltech Coppens has taken control of how its production facility impacts the world around us.

Rethinking the use of plastic

As an aquaculture company, we must play our part in feeding the world responsibly and making the benefits of the circular economy for business clear: More effective use of materials means less waste. We are driving our approach through a commitment to reshape our plastic use. Alltech Coppens’ objectives are aligned with the long-term aims of Working Together for a Planet of Plenty™, as well as the United Nations Sustainable Development Goals. Sometimes, rethinking what you have always done is the best way to make an impact and recycle effectively. As part of our commitment, we aim to focus on reducing our use of materials. Alltech Coppens believes rethinking our packaging contributes to the SDGs. We decreased the variation of our standard packaging from five to two designs and changed wrapping foil thickness. By doing this, we reduce the use of our materials drastically and save 500 kilometres of plastic annually! Our packaging is and will remain 100% recyclable. We will continue to take steps toward more sustainable aquaculture practices. We are proud of the continuous efforts we are making to reduce our footprint as we amplify our global presence.

Circular waste management

At Alltech Coppens, we focus on utilising resources responsibly and producing in sustainable ways that will help mitigate the harm inflicted on the planet. To ensure sustainable production, we have established a comprehensive waste management system. When producing high-quality feeds, each production batch needs to be fine-tuned. If our first output does not meet quality standards, it is deemed ‘rework.’. These quality standards include shape and size. During the production process, we sieve the fish feed at different stages. This ensures that when a customer orders 3 mm pellets, they only receive 3 mm pellets. The pellets that are too small or too large are collected and become rework. Because we have 100% traceability, we know exactly which raw materials are in this rework. We can then specifically reprocess these in production so that nothing goes to waste.

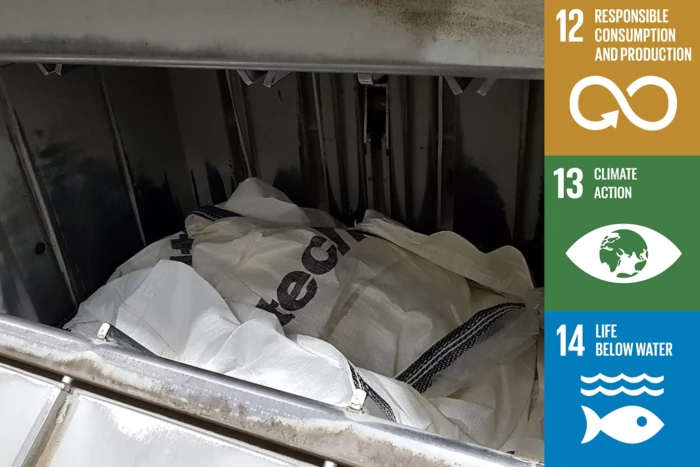

Nearly all rework that emerges in our production is re-used in our production. If we cannot re-use it, we sell this feed to a bio-fermenter, which produces energy from this feed waste! Third parties also re-use broken and old wooden pallets, plastic packaging material, dirty and used big bags and IBC tanks. Plastics and big bags are reprocessed into recyclate, which is used for new packaging, while leftover oil and fat are used to generate energy. Cartridges and lids also still have value after use. Alltech Coppens donates empty cartridges to Stichting Dierenlot, a Dutch charity that supports local and regional, small and medium-sized organisations that rescue animals in need.